ASSET INTEGRITY MANAGEMENT POLICY

Commitment

As Zorlu Enerji, we are committed to maintaining the highest standards of asset integrity management to ensure the safety of our employees, the reliability of our operations and the sustainability of our geothermal energy solutions.

Aim

We implement a comprehensive Asset Integrity Management System in line with industry best practices to ensure the safe, efficient and sustainable operation of our geothermal power plant assets.

Policy Principles

1. Risk Based Approach

- We prioritise asset management activities based on risk assessments, focusing on critical areas that impact safety, reliability and performance.

2. Life Cycle Asset Management

- We apply integrity measures throughout the asset lifecycle, from design and commissioning to operation, maintenance and decommissioning.

3. Preventive Maintenance

- We implement a predictive and preventive maintenance programme to minimise unexpected failures and optimise asset performance.

4. Compliance with Legislation

- We comply with national and international standards and regulations to ensure the highest standards of operational integrity and environmental responsibility.

5. Continuous Monitoring

- We use advanced monitoring technologies and data analytics to monitor asset condition and proactively identify potential problems.

6. Training and Qualification

- We provide regular training for employees and contractors to support their awareness, technical skills and compliance with security and integrity protocols.

7. Emergency Preparation

- We develop and test emergency response plans to reduce the risks of asset failures or operational interruptions.

8. Sustainability Integration

- We align asset management practices with Zorlu Enerji's sustainability goals, including energy efficiency, emission reduction and resource optimisation.

9. Stakeholder Engagement

- We collaborate with stakeholders, including regulators, local communities and industry partners, to promote transparency and accountability.

10. Continuous Improvement

- We regularly review and update asset integrity processes based on performance results, technological developments and changing industry practices.

AWARENESS AND EDUCATION

OHS trainings are given regularly to all employees and contractors on a compulsory basis. OHS trainings both protect the health of employees and contribute to business continuity by preventing accidents and unexpected stoppages in the workplace.

In the scope of training,

General hazards and risks at the workplace,

Selection, correct use and maintenance of personal protective equipment,

How to identify hazards in the workplace and how to manage risks,

Information is given on topics such as safe working with machines, tools and equipment.

ASSET MANAGEMENT PLAN

Periodic equipment checks are carried out regularly as part of our asset management plan to ensure operational reliability, safety and compliance with relevant standards. These checks help to identify potential risks, maintain optimal performance and extend the life of critical assets.

PREVENTIVE AND CORRECTIVE ACTIONS & CONTINUOUS

Preventive and corrective actions are key components of our commitment to continuous improvement. Preventive actions are taken proactively to eliminate potential risks and prevent problems before they occur, thereby ensuring continuous performance and minimising downtime. Corrective actions are taken when deviations or non-compliances are detected, to prevent recurrence by addressing root causes. These actions form a continuous improvement cycle that increases efficiency, improves safety and supports the long-term sustainability of our operations. Planned maintenance is carried out to prevent breakdowns.

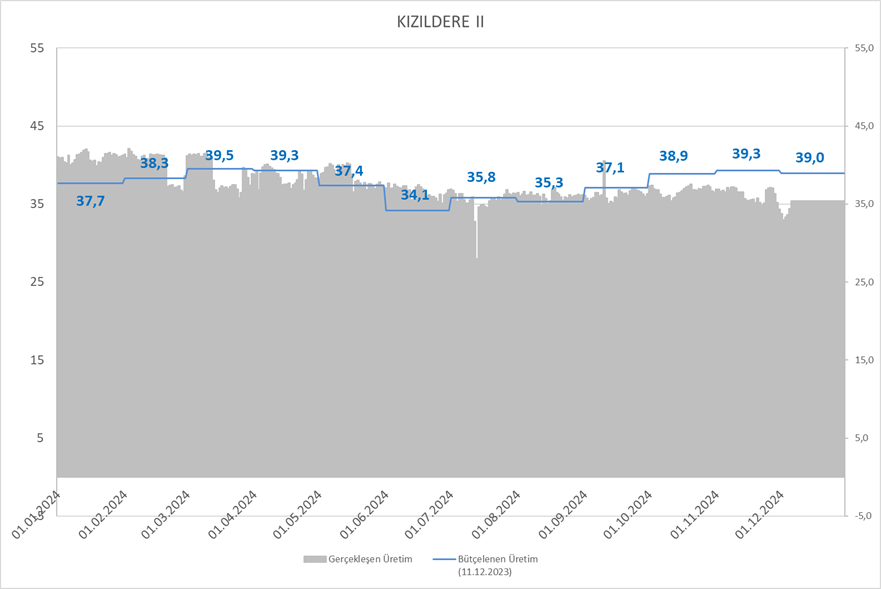

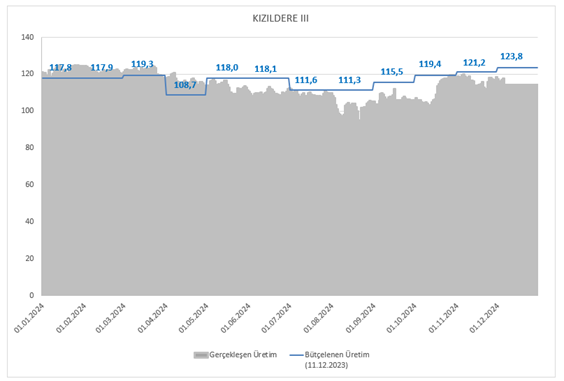

DISCLOSURE OF SPECIFIC ASSET MANAGEMENT OBJECTIVES AND TARGETS

The Company's asset management targets include ensuring production in line with the budget. This target is managed through a continuous monitoring process in order to monitor and meet the targets set according to the annual production plans. The ‘Production (MW)’ metric, set as a KPI, is used to monitor the extent to which this target is realised. Thus, effective management of production capacity is ensured

REGULAR INTERNAL OR EXTERNAL AUDITS

At Zorlu Enerji, we conduct regular internal and external audits within the scope of asset integrity management and focus on ensuring the reliability and sustainability of our operations. We conduct these audits in accordance with SEVESO and ISO 9001 standards.

We manage risks and take necessary safety measures to prevent major industrial accidents through SEVESO audits.

We evaluate the effectiveness of our quality management systems and support continuous improvement processes through audits within the framework of ISO 9001.

Through these audits, we regularly monitor both our operational integrity and the quality of our business processes and realise opportunities for improvement.

RISK IDENTIFICATION AND MITIGATION STATEMENT

As a company, we continuously monitor the risks identified within the scope of SEVESO and implement the necessary risk management strategies to minimise the identified hazards. This approach is of great importance in terms of occupational safety and environmental protection and helps prevent potential accidents. We take all necessary measures to effectively identify and minimise risks.

MONITORING AND MEASUREMENT OF PERFORMANCE

Our performance monitoring processes include systematic data collection, analysis and reporting steps, and we use the findings obtained to mitigate risks, evaluate opportunities and improve decision-making processes. In addition, we manage performance data in accordance with the principles of transparency and accountability by verifying them through internal and external audits.

MANAGERIAL RESPONSIBILITY

The operation manager and operations group manager are responsible for maintaining the availability of the geothermal plant. Within the scope of this responsibility, they operate the asset integrity management system.